PWM Solenoid Driver / Control

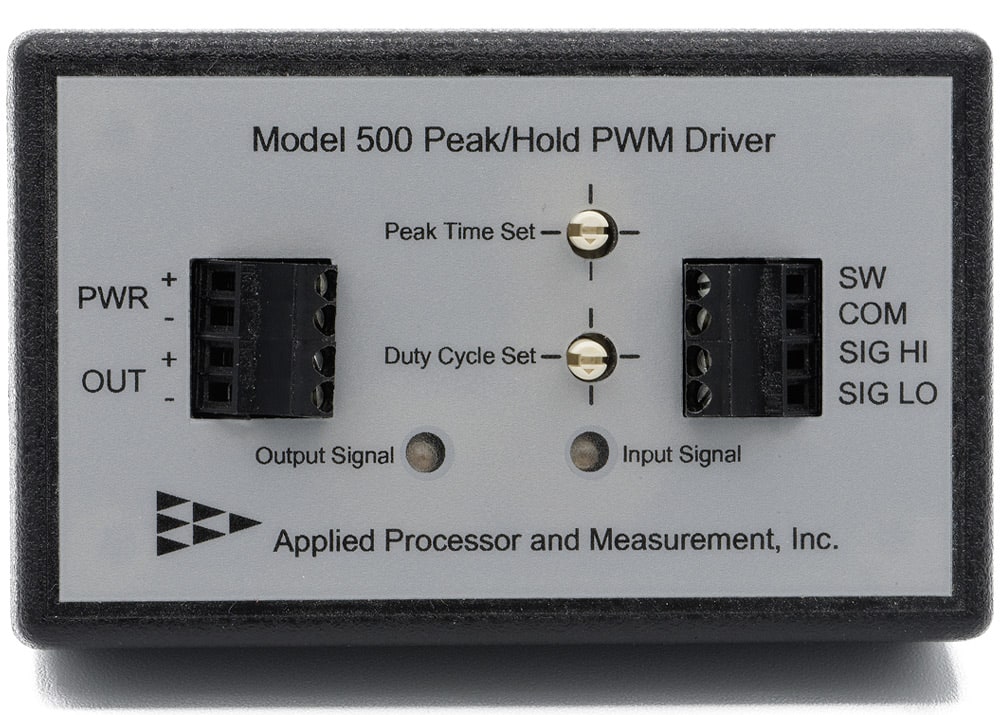

Model 500 Peak and Hold PWM Driver

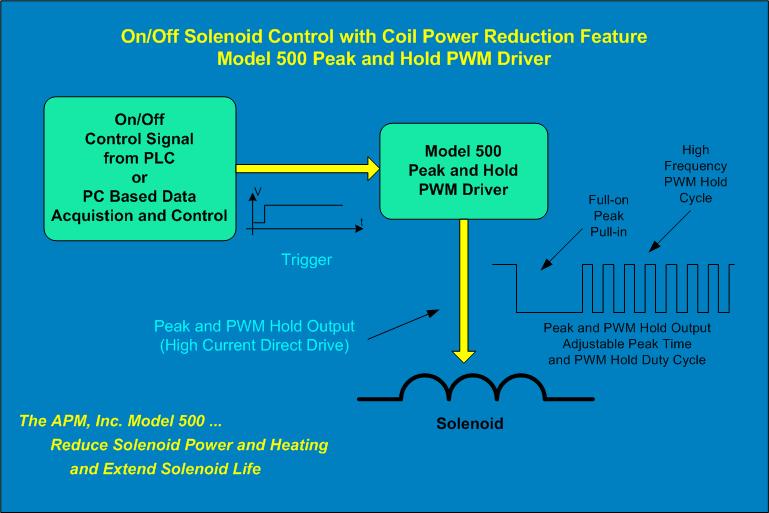

The Model 500 Peak and Hold PWM Driver (also known as Pick and Hold PWM Driver) is intended for on/off solenoid control applications where reduction in power and coil heating is required. The Model 500 is suited for solenoid control applications where a digital output from a PLC or PC data system is used.

The Model 500 uses timed peak and hold settings. For current controlled peak and hold, see the Model 805 Driver.

The Model 500 Peak and Hold (also known as Pick and Hold) Driver is designed to drive solenoid devices with an initial full-on pull-in pulse, then provide a reduced power hold-in current by pulse width modulating the output. The high frequency PWM output provides enough hold-in for the solenoid, while the current reduction saves overall power and reduces solenoid heat, thereby saving energy and extending coil life. The Model 500 readily interfaces to PLC and computer controls in industrial applications.

| Control Modes | PWM Frequency / Duty Cycle |

|---|---|

| Stand-alone | Peak Times adjustable from 5msec to 5sec |

| Optically isolated trigger | 15% to 90% Duty Cycle, adjustable in 5% steps |

| Contact closure trigger | Frequency Low/High Range selectable |

| Low: 500 to 1500Hz, High: 1000 to 25000Hz |

| Input / Output | Output |

|---|---|

| 4A continuous output, 6A peak | Customized settings available for: |

| Low-side drive, open drain power MOSFET | Frequencies |

| 9V to 28V DC powered | Peak Times |

| 5V to 28V level trigger input | Hold Duty Cycles |

| Contact trigger input | 5V only output drive signal |